Unveiling the Lifespan of Plastic Pallets: How Long Do They Really Last?

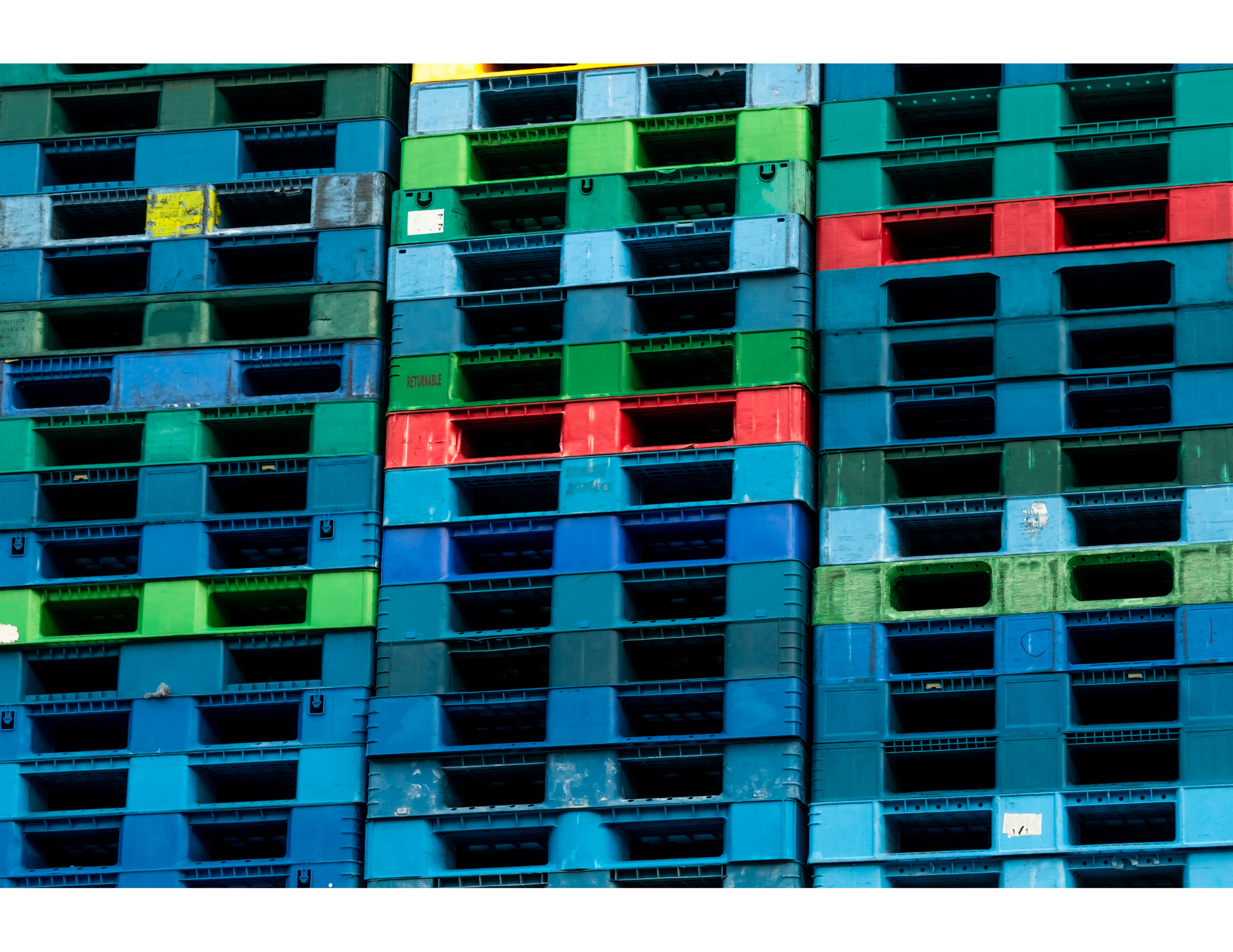

Plastic pallets are an indispensable asset in the world of logistics, offering durability, versatility, and sustainability. But have you ever wondered: what is the life of a plastic pallet? In this blog post, we’ll delve into this question and explore the factors that determine the lifespan of plastic pallets, shedding light on their longevity and durability in various industrial settings.

Understanding Plastic Pallet Lifespan

Plastic pallets are engineered to endure the rigors of transportation, handling, and storage in demanding industrial environments. Unlike their wooden counterparts, plastic pallets are resistant to moisture, pests, and rot, factors that contribute to their extended lifespan. However, several factors influence the longevity of plastic pallets:

- Quality of Materials: The quality of the materials used in manufacturing plays a significant role in determining the lifespan of plastic pallets. High-quality materials ensure structural integrity and resistance to wear and tear over time.

- Design and Construction: The design and construction of plastic pallets impact their durability and longevity. Pallets with reinforced corners, sturdy feet, and uniform weight distribution are less prone to damage and deformation, resulting in a longer lifespan.

- Frequency of Use: The frequency and intensity of use affect the lifespan of plastic pallets. Pallets subjected to frequent handling, heavy loads, and harsh environments may experience accelerated wear and require replacement sooner than those used infrequently or under lighter conditions.

- Maintenance and Care: Proper maintenance and care can extend the lifespan of plastic pallets. Regular inspection for damage, cleaning to remove debris and contaminants, and repairs when necessary contribute to prolonged durability and performance.

- Application and Environment: The specific application and environmental conditions also impact the lifespan of plastic pallets. Pallets used in industries with stringent hygiene standards, such as food and pharmaceuticals, may have a shorter lifespan due to the need for frequent cleaning and sanitization. Similarly, exposure to extreme temperatures, UV radiation, and chemicals can degrade plastic pallets over time.

Benefits of Long-lasting Plastic Pallets

Investing in high-quality plastic pallets with a long lifespan offers several benefits for businesses:

- Ease of Maintenance: Plastic pallets need not go through treatment to prevent growth of fungus or mould nor insect infestation; making them extremely easy to maintain.

- Quick Cleaning: As a good hygiene practice, plastic pallets can be easily cleaned utilising various methods such as hot wash, steaming or chemical solution.

- Safety: Moulded sleek and splinter free plus their lightweight feature, plastic pallets are easier and safer to handle.

- Cost Saving: Being 30% lighter than wood pallets, it is a logistically wise choice for its great transportation savings.

- Durable & Robust: A life span of up to a decade, the durable and robust plastic pallets can function with hardly any breakage; greatly reducing the need or cost to repair or replace them.

- Recyclable: Even after many years of usage, plastic pallets retain their value by being recyclable. Churned out again as new pallets, they can be used for multiple years; an environmentally friendly and sustainable solution.

Conclusion: Maximizing the Potential of Plastic Pallets

In conclusion, the lifespan of plastic pallets varies depending on factors such as material quality, design, usage, maintenance, and environmental conditions. By understanding these factors and investing in high-quality pallets, businesses can maximize the lifespan of their plastic pallets, reaping the benefits of durability, reliability, and sustainability in their logistics operations.

For businesses seeking durable and long-lasting plastic pallet solutions, Mah Sing Plastics offers a wide range of industry-tailored pallets engineered for optimal performance and longevity. Explore our selection of plastic pallets here and elevate your logistics strategy with quality and durability you can trust.