Black is the New Green in Logistics

We live in a plastic era where our lives are so dependent or surrounded with plastic; from the packaging of our online shopping, take-away containers, detergent bottles etc. Such a prominence it is that its accumulation is an ongoing, expanding issue that we have to deal with.

Organisations across the industries are thinking of ways to incorporate better business practices that will help preserve the environment. Sustainability is no longer an option but a mandatory factor moving forward if mankind is to safeguard the environment for the next generation.

Kindness in Plastic

Kindness in plastic pallet industry comes in the form of recycling plastic for its manufacturing. Instead of relying on virgin plastic, recyclable elements are being utilised to produce environmentally friendly plastic pallets.

However, in order to produce plastic pallets which are uniform and environmentally friendly, it comes with a prescribed condition in the form of colour selection.

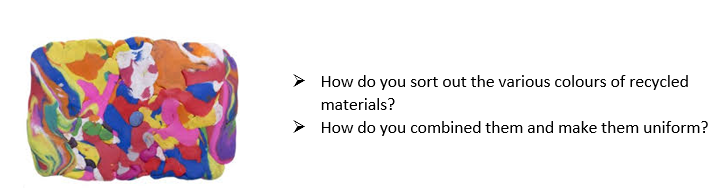

When it comes to recycling plastic, colours play a large role in its final outcome. The plastic elements being recycled come in many forms and colours. Once combined, they unfortunately do not produce uniform colour that is pleasant looking which is a desire or requirement from the clients.

As with many products out there, the market demands finished goods which are attractive or at least pleasant looking, uniform and consistent.

One effective way of overcoming this mishmash of colours is to add in black pigment resulting in uniformity. It is simply an easier method to produce product consistency rather than having to sort recycle plastic by colour in order to create plastic pallets in various colours.

It is for this reason that black plastic pallets generally indicate they are made from recycled plastic. Recycling plastic in this matter makes the whole process more time and cost efficient.

Circular Business Model in Plastic Pallet Industry

As mentioned in the previous paragraph, manufacturing plastic pallets from recycled materials have been incorporated within the industry; creating a circular business model where the materials and products used are kept for as long as possible to get the maximum value from them.

With this business practice, the manufacturer will require less sourcing of new materials which in turn is kinder to the environment with less energy consumption in producing the raw materials.

However, this model will only be sustainable if there is market demand. If most clients are demanding and will only accept plastic pallets in vibrant colours of their choice, then it will no longer be viable model for the manufacturers who need to invest a great sum in the recycling machinery etc.

Some may not opt for plastic pallets made from recycled materials due to the impression that they are of inferior quality but the truth is far from it.

Recycled vs. Virgin Plastic

When it comes to satisfying the criteria required of plastic pallets, both recycled and virgin plastic are well able to do so.

Both types are : –

- Hygienic : Non-porous material with resistance to moisture preventing build-up of mould

- Easy to Maintain : Easy to clean surface which can be sanitised with steam or chemical

- Safe to Use : Plastic used to make pallets such as PP, HDPE or its recycled counterpart has no issues with chemical leaching making them safe even for food shipping including meat, dairy products etc.

- Safe Handling : Easy to handle being lightweight and splinter free

It is great to learn all the facts and benefits before you select your choice of plastic pallet that will be most advantageous to your business.

If you need detailed information on the suitable type of reliable plastic pallets for your industry, please reach out to our product specialist here